Another

cold day with 7 degrees in the van and 3.7 degrees outside at 7.30am. Starting

to cloud over and there is only a small amount of frost. Nice colour as the sun

comes up.

Put

on leggings under the jeans today after freezing yesterday. At 9am it was still

on 6 degrees outside!! The breeze is picking up too. Drove down to Clarence Point esplanade – Mr

Freeman has been here too.

Into

Beaconsfield to check out the museum and mine. The clouds are moving on so

should be a nice day after all. Picked up a history walk brochure so went off

to do that first. Beaconsfield is now a modest apple growing centre in

Tasmania’s north. It was once the wealthiest gold town in Tasmania. It began

its early life as ‘Brandy Creek’ because of the colour of the water in the

creek where the gold was originally discovered.

Stopped

at the park near the museum where there were panels like the ones in Westbury.

And

a waterwheel.

Across

the road was a replica Miner’s Cottage which was all decked out, complete with

hessian ceiling.

Next

to it was a very small building which was the Sidmouth Shop (down the road from

here near the Tamar River). It was the general store and oil depot that service

the orchard and farming areas of the Tamar Valley during the 1930s to 41. The

shopkeeper was Mrs Barbara Swain, whose family conducted a bus service. It was

donated to the museum in 1989 by the Hickman family.

Next

was the Flowery Gully School, 1891 to 1937. It was relocated and erected here

by volunteers in 1977.

I

remember making cotton reel knitting – Dan even did this too.

They

even brought the dunnies.

What’s

left of the original buildings of the gold mines have been saved. The boiler

room on the left and The Hart Shaft.

The

Grubb Shaft 1905.

With

the modern tower over the mine shaft.

Inside

we head into the museum. Info about the last 30 years of the mine.

First

through all kinds of machinery.

Old

apple truck – 1928 Manchester from England, side valve 4 cylinder engine, 16hp,

2.5L.

There

was lots of hands-on machinery. I had a go at turning the handle on a vacuum

pump (c1910) which was used in milking sheds. They couldn’t find the parts to

restore it to full working condition so they added a whistle from a steam

traction engine and a hand wheel from an old laundry mangle. Boy did I laugh

when I turned the handle and it made a farting sound – Steve said it was the

air being sucked in. As I turned the handle faster I made the whistle blow. Should

have taken a video as it sounded so funny when the next lady had a go.

This

looked interesting - Cross Cut Drag Saw (c1928) – very rare single cylinder,

self-propelled on three land wheels.

Next

was a room all about the mining and the tragedy rock fall in 2006.

Climbed

into the tunnel and put my head up to look into the cage that the two miners

were stuck in for all those days. Certainly was cramped. I would have gone mad.

Another

section all about communication. Steve was Superman calling me in the Exchange.

This

collection of 150 wooden knobs was started in 1985 by Ray Porter of

Beaconsfield. They are gathered from within Tasmania and other parts of

Australia.

The

Tassie timbers we have been seeing – even a Manfern.

Another

section about the West Tamar area.

An

apple sorter and corer/peeler. Amazing how someone worked all this out to get

all the wheels etc to do the job. It was one of six used in the Jones and Co

IXL factory at Beauty Point. The factory initially opened during the first

world war for exporting dried apples and later extended its operation to

canning the fruit.

Beauty

Point info.

A

map of historic York Town which is up the road from here and was the first

permanent settlement in northern Tasmania.

Some

sidecar riders racing on Greens Beach.

The

surgical ward always makes us glad we live in this era of time.

Steve

peering out the window of the ‘home’.

Found

out how to make a rag rug.

Into

the next section which was the Grubb Shaft Engine House (built between April

& August, 1905). The massive walls

were needed to support a gantry for a travelling crane. This building, plus the

boiler house and the Hart Shaft building, used 1,050,000 bricks. Including the

shaft work, 13,398m3 of cement was poured. The biggest problem they had with

this mine was there was too much water flooding into the mine shafts. Lots of

information about the mine from 1847 to 1914.

Great

photo of the mine and town looking east taken about 1902.

Lots

of machinery etc to check out.

Some

quartz samples with gold in it, taken from 850 meter level of the Beaconsfield

Mine.

The

doors are made of Pitch Pine which is the strongest and most durable of all the

pine tree family. Used for decks and masts of sailing ships, bridges and

pilings, its high pitch (resin) content ensured a long and useful life. The

pitch pine used without the centre such as these doors, was part of a massive

1500ft (457m) pump rod used in the Tasmanian Mine from 1905 to 1914. The rare

and beautiful timber was supplied by the Hathorn Davey Pump Co of Leeds,

England, who probably obtained the timber from the southern states of USA.

The

people behind the mine.

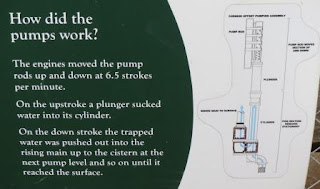

How

the pump worked. There is a small scale version which works.

Timber

and cage skids etc from the Hart Shaft.

A

scale model of ‘workings’ of the Tasmania Reef, Beaconsfield (1 : 473 -

950mm = 1500ft) when mining ceased in 1914. It’s amazing to think of all

those men that far down underground. The

mine yielded 26.5 tonnes of gold (1878 to 1914)

The

door handle and three locks on the strong room door which was relocated from

the former Luck Bros building in Devonport. It was thought to be on the bullion

room at the Tasmanian Mine Battery at Middle Arm. It weighs more than half a

ton and was made in Launceston.

Into

the next big shed which was the boiler room. The Horse Drawn Water Cart.

A

Clayton Shuttleworth, 12hp portable steam engine, built in 1883 was used at

Ophir Gold Mine, Beaconsfield.

Furphy’s

Farm Water Cart. Earlier models of these horse-drawn water carriers were in

common use in Army cook houses during World War 1. The cook always knew the latest

news, hence in Australian slang, a ‘furphy’ = a rumour or a tall story. The

short-hand on the end of the tank reads ‘Water is a gift from God, but beer is

a concoction of the Devil, don’t drink beer.’

A

much larger version of this Jackass Steam Boiler would have been erected here.

Between

the sheds is the water wheel. Steve pressed the button and it came to life and

then the belts turned the stamper heads which crushed the quartz to retrieve

the gold. Took a video of it working then forgot to take a photo of the wheel

and stamper!!

Out

the building around to the ‘Monkey Cage’ where we look down on the spot where

Todd Russell and Brant Webb emerge from the cage after being trapped deep down

in the mine. They were actually a long way from here, down under the police

station on the main road.

The

supports to keep the old walls erect above where we were in the boiler shed

area.

Down

to the pump area – remaining walls.

Only

the base remains of the huge chimney.

A

miner’s hut, water pump and cradle.

Steve

panning for gold again – and he found some!! Already moulded too!!

The

original Grubb Mine shaft is all collapsed. You can see the pump rods.

The

Engine/Pump house is behind us (where we were before). A plaque outside reads -

This large brick and steel building 79 x 131 feet (24 x 40m) was built in 1905

to house 22 steam boilers, 13 of which were installed. Steam power was used

throughout the mine.

A

time line info board.

Out

onto the newer mine yard. The tripod design of the headframe resulted from a

previous shaft failure due to unstable ground surrounding the shaft. The

likelihood of subsidence meant the headframe may need to be adjusted. By

constructing the headframe as a tripod, it would be easier to adjust than if it

were a square. The tripod also keeps the load well away from the shaft collar.

The

Sheave that guides the winder rope at the top of the headframe. The shaft is

the only way the ore came out and the main way out for the miners. This spare

sheave was always ready for use if needed.

The

ore skip that goes under the cage. It brings about 4.5 tonne of ore to the

surface each time.

The

ore skip and cage lying down.

Steve

escaping from the cage. Concreted in now. Looking up at the cabling above.

Steve taking tag off the board to say he was back on the surface.

Walked

into the area under the headframe where the ore is tip out of the big bucket

and onto the conveyor belt that takes it to the crushing plant. Looking up to

where it would have tipped from.

Where

the ore would have tipped into the container then onto the conveyor belt.

Climbed

up the stairs to look inside where the bucket would slide over these arms to

make it tip out the ore.

Down

the shute – might be some gold stuck in that!! Then down onto the belt.

Looking

up the headframe.

Further

up the stairs was a lookout point with info boards in two directions.

Looking

up to where we were up the stairs.

Into

the Winder House that winds the cable that lifts the cage and bucket up and

down the shaft.

On

one of the legs of the headframe tripod is a small plaque remembering Larry

Knight who died in the rock fall. There wasn’t too much about him – mainly the

two that survived.

The

other side of the headframe with the conveyor belt.

Yes

we did ask this question – where does the poo go!!

Wagner

ST-2 Scooptram. Amazing to think how they get these down the shaft and that

there is enough room down there to drive them around.

Another

important aspect – how they get fresh air.

The

big machines of the old days.

The

small kibble was used during rehabilitation of the shaft. A miner says – ‘Three

of us used to get in and go down the shaft. It was very intimidating the first

time – it’s a long way down. When we used to get down to the job, we’d put

stage boards across the shaft and then we’d shovel all the dirt into this…’ The

bigger one – the miner’s comment – ‘We used to put it half full of dirt because

it’s a long way in and you can’t see nothing!’

Into

the miner’s change rooms. There was a clean entrance and a dirty entrance and

they had to go through the shower room between the too. Oops someone was

showering!!

The

deeper you go underground, the hotter it gets. In Tasmania the geothermal

gradient is about 2.5 degrees Celsius. Every 100 metres you go below the ground

the temperature gets 2.5 degrees hotter. At the 1080 metre level, the

temperature was about 32 degrees C and the humidity, about 90% - sounds like

heaven to us!! The miner’s comment – ‘Some days underground you would get that

bad, you would empty sweat out of your gumboots several times a shift and I

don’t mean a spit full, you empty cup fulls.’

Steve

was amazed how in the early days they reinforced the timber posts by encasing

them with steel.

In

another shed was the drill sharpening workshop.

Don’t

look like these drill bits would cut anything but Steve said they hammer and

grind the rock rather than cut it.

This

gold melting furnace burned 200 litres of diesel an hour to reach the

temperature needed! It was used as Lefroy in the 1980s when the tailings from

the historic gold mines there were being reprocessed.

Back

through the gift shop where I bought a gold charm in the shape of Tasmania.

Back out to the truck looking at the Grubb Shaft (1905) and boiler room then

the Hart Shaft (1904) buildings. The Hart Shaft Engine House once housed the

pumping and winder engines for the Hart Shaft. Only one third of the original

building stands today and has been redeveloped as the winder house for the

current mining operation, Beaconsfield Mine Joint Venture.

Info

board was the first one of the Walk of Gold that we did first.

Looking

at the water wheel and then an old cage and ore skip.

A

plaque commemorating the townspeople of Beaconsfield for the community spirit

throughout the mine tragedy in 2006.

Up

behind the Mine Manger’s residence (now the Council offices) is the site of the

Ballarat Gold Mine – unfortunately they haven’t maintained these info boards. I

had picked up a brochure - In June 1877

the Dally brothers found 47 ounces of gold at Brandy Creek. This started a gold

rush and a year later there were 700 men on the field. In December 1878the

Ballarat United Gold Mining Company was registered with a capital of 4,800 one

pound shares. Beaconsfield’s first mines were alluvial, but water was in short supply

and the ore had to be carted to the creek for sluicing, adding to the cost of

production. When mining went underground, the opposite occurred – there was too

much water! No-one wanted to be the first to put in pumps. They were expensive

to install and operate – and because they mines were so close together, pumping

in one mine would alter the water table in the next shaft and no-one wanted to

benefit his rivals by doing their pumping for them. The Ballarat Gold Mine’s

pumping machinery began operation on 9th December, 1878 and eight

days later the mine was 80 feet deep. The shaft reached its final depth of 210

feet (over 60 metres) in August 1879. The Ballarat Gold Mine is now an

archaeological site – all that remains of Beaconsfield’s small independent

mining operations.

The

site of the shaft.

Where

the boiler room was.

Headed

off back to the truck via Beauty Point. It is the heart of a rich sheep, cattle

and vineyard district. This tiny township was the first deep-water port on the

Tamar River and was first established as a port to service Beaconsfield. The

original wharf, where the first deep-water vessels arrived, is now the site of

the Australian Maritime College. It is also the starting point for the

Launceston to Hobart yacht race held the same time as the Sydney to Hobart

race.

Lots

of little birds have moved in.

Across

the river is the woodchip mill and Comalco at Bell Bay.

5pm

and the sun has gone down so drove home in the dark – so different to when we

first came.

Heater

on and I checked the temp at 10pm, 6.7 degrees.

No comments:

Post a Comment